EN 50126

RAM-Nachweis, Sicherheitsnachweis, Validierung nach EN 50126, EN 50128, EN 50129

Railway RAMS specification ram verification safety case EN 50126, EN 50128, EN 50129

Railway Applications - The Specification and Demonstration of Reliability, Availability, Maintainability and Safety

As experienced engineering partner, we are professionals in defining requirements, performing RAMS management and for the demonstration of reliability and safety in railway applications.

EN 50126 represents, with the parallel applicable standards EN 50128/EN 50657 and EN 50129, the area-specific adaptation of the basic safety standard EN 61508 for the railway industry. The standard EN 50126, which is mandatory according to the IRIS (International Railway Industry Standard) regulations, applies to all areas of railway technology. It is required for train protection and signaling (signaling technology), to rolling stock and to fixed installations.

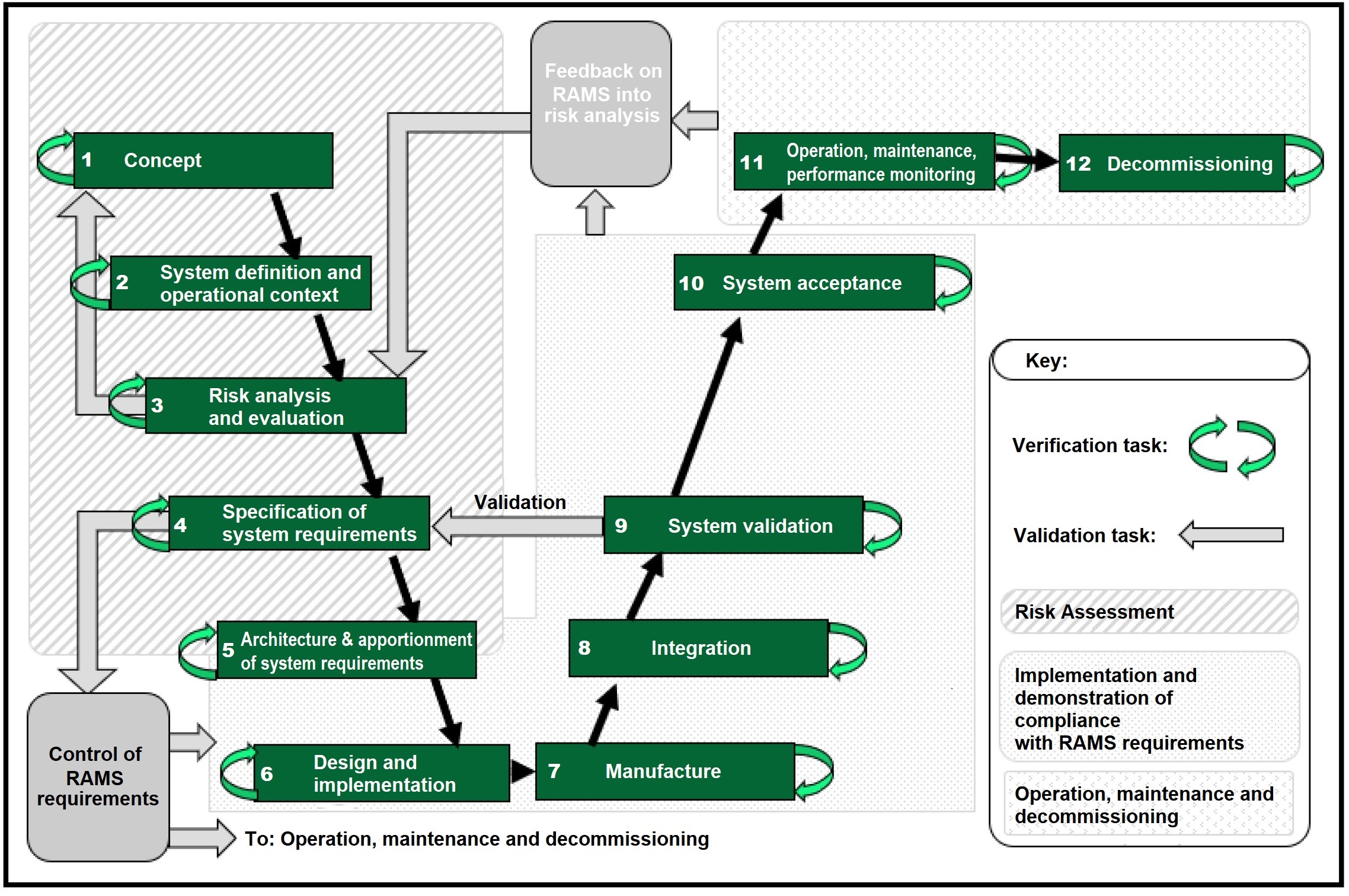

The standard deals with the definition and verification of RAMS for all railway applications and at all levels in all relevant life cycle phases.

EN 50126 is primarily intended for use by railway companies and railway suppliers. However, it has a generic content that it can also be used for other areas outside of railway applications with regard to a systematic RAMS/LCC specification and verification.

Since the update in 2017, EN 50126 has consisted of two parts:

- Part 1: Generic RAMS Process

- Part 2: Systems Approach to Safety

Part 1 defines the terms behind the acronym RAMS and covers the generic aspects of the RAMS lifecycle. For this purpose, the RAMS-related tasks are defined in the individual life cycle phases and a systematic process for determining RAMS requirements is described.

Part 2 covers the safety-related generic aspects of the RAMS lifecycle and associated procedures and tools, and provides an understanding of the systems approach to safety. Instructions and procedures are presented.

Both parts do not contain RAMS target values in detail, requirements or solutions for specific applications. It also does not include any rules or processes for certification or the approval process.

RAMS life cycle according to EN 50126

Important standards in relation to EN 50126

General basis standards

Important standards, which complement EN 50126

We help you with the planning, analysis, verification and validation of the necessary RAMS tasks in all life cycle phases.

For you as a supplier, we take over the preparation of RAMS plans, the implementation of risk analyses, the producing of RAMS forecasts, the RAM and safety verification including the documentation of the fulfillment of the RAMS verification tasks as well as the validation.

We support you as the operator with the system specification and with the preparation of the RAMS requirements, with the identification of hazards and the risk determination in connection with the failure and impact analysis and with the quantification of the risk that is still tolerable.

In the operation and maintenance phase, we offer you suitable solutions for the continuous recording of the RAMS-related performance of the systems.

As an external partner, we guarantee the independence of the roles required by EN 50126-2.

Depending on your role in the project, we offer you the following services:

Concept phase – risk assessment (RAMS phases 1-5)

- identifying the RAMS effects of the system concept

- identifying RAMS requirements for similar systems

- identifying the RAMS-related strategy and RAMS-related goals

- establishing of the RAMS plan and the validation plan

- facilitation of the RAMS risk analysis

- establishing the RAMS requirements specification

- establishing and updating the hazard log according to CSM-RA and the RAMS management report

Implementation and demonstration of compliance with the RAMS requirements (RAMS phases 5-10)

- updating RAMS and validation plan

- updating RAMS analysis

- performing RAM and safety demonstration

- updating the RAMS management report

- establishing the RAMS validation report

- definition and coordination of the application conditions for the system (SRAC)

- updating the hazard log

Operation, maintenance and decommissioning (RAMS phases 11-12)

- implementation and maintenance of a FRACAS process

- continuous reporting on RAM performance and evaluation

- evaluation of the RAMS-related impacts of decommissioning and disposal

- updating the operator’s hazard log

Questions and answers about the implementation of EN 50126

Which RAMS documents need to be created and updated during the life cycle?

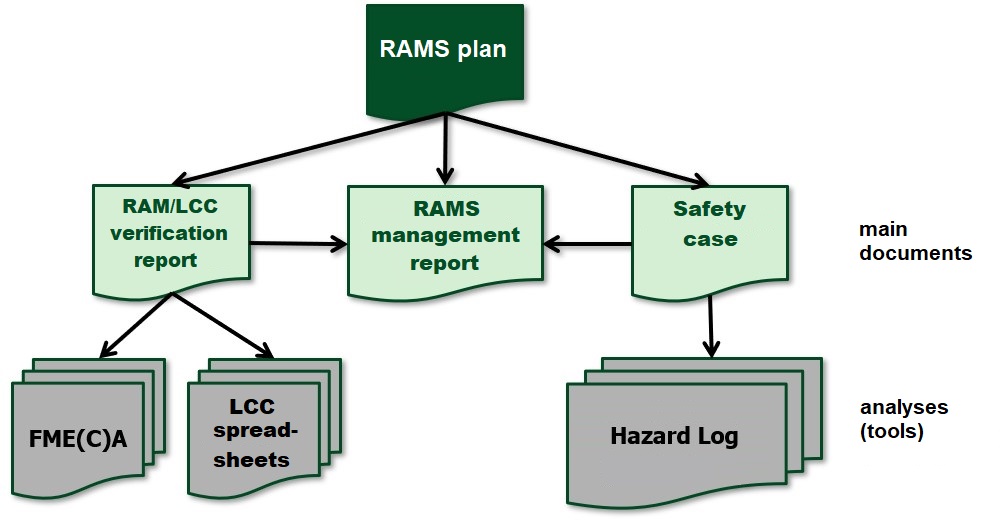

The basis for RAMS management over the entire life cycle is the combined RAMS plan. The verification in relation to the RAMS requirements is usually divided into three documents due to the different objectives and content: the RAM verification report and the safety case as well as the validation report.

Depending on the scope and complexity of the project, the first two verifications can also include the results of the RAMS management process for each life cycle phase.

Keeping a separate RAMS management report has proven to be a viable solution to avoid duplication and discrepancy.

What is the RAM verification report for?

The RAM verification report documents the feasibility of the required RAM properties of the system under consideration. The relevant system requirements for environmental conditions, supply systems, stocking of spare parts and maintenance are considered accordingly.

The methods FMEA, FMECA, FTA are primarily used as tools for RAM verification. The results show in an analytical way under which conditions the determined RAM parameters are met.

The RAM calculations are based on input values which, if possible, are specified and confirmed by the manufacturers of the components used.

If no manufacturer information is available, suitable reference values from comparative projects or expert estimates are used as an approximate solution. All input values are checked by the responsible experts with regard to plausibility, transferability and applicability to the system under consideration.

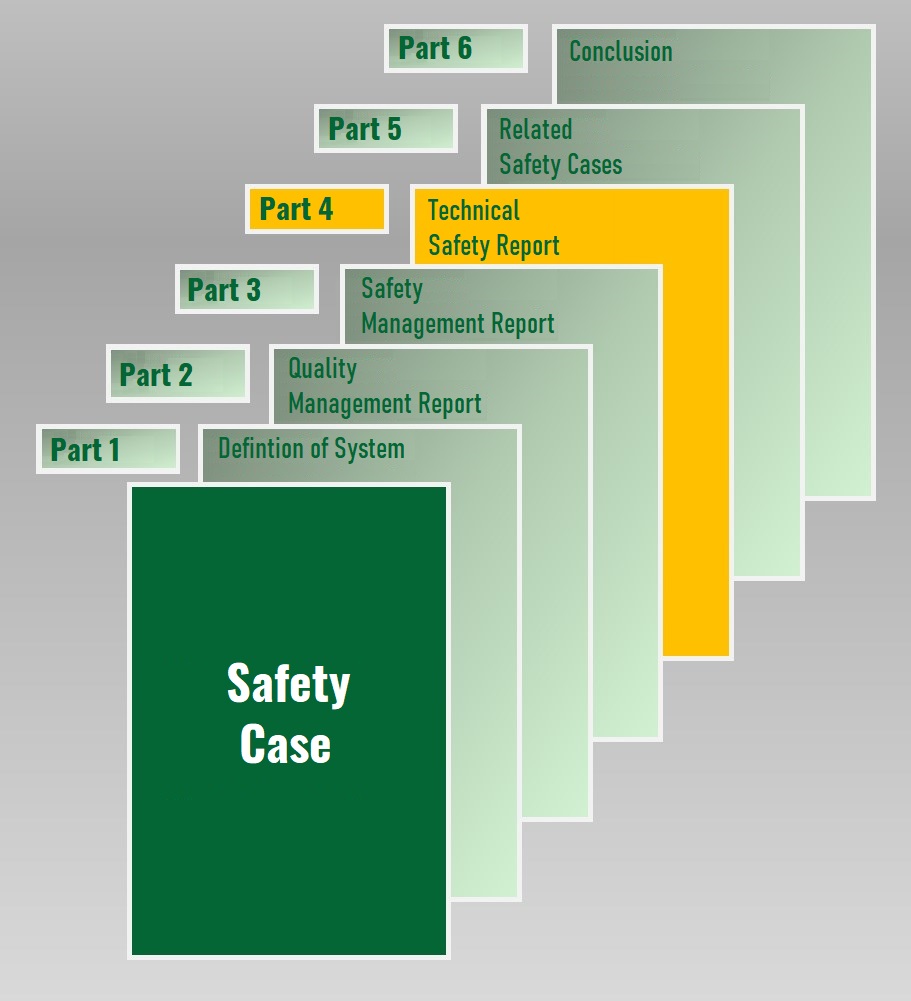

What content does the safety case for railway applications include?

The safety case assesses whether the system under consideration is suitable for meeting the quantitative and qualitative safety targets from the safety requirements based on current aspects in accordance with the intended application conditions. The verification focuses on the systematic recognition and classification of all hazards that can be foreseen under normal circumstances and the determination or evaluation of the system risk for each hazard as well as the derivation of suitable risk reduction measures.

The results of the safety analyzes are documented in a hazard log.

Relevant operating and environmental influences, the safety-relevant application conditions, as well as general working and application conditions of technology and people are considered.

The outline proposed in EN 50129 is proven for structuring the safety case, especially for railway applications.

The responsibilities for the RAMS management tasks in the life cycle depend on the respective RAMS phase. The operator/client bears the main responsibility for the first life cycle phases up to and including the determination of the system requirements, whereby the supplier, who, like the operator, has to start a comprehensive risk analysis in phase 3, must be involved in this process at an early stage.

The responsibility of the supplier begins with the architecture and apportionment of the system requirements and ends with the system acceptance, from which it changes back to the operator and applies until decommissioning.

Depending on the type and scope of the project and the technical system, there are other parties involved in this process (e.g. independent experts and supervisory authorities).

Subcontractors and suppliers have similar tasks to those of the main contractor.

The following tasks and activities of the RAMS management are particularly noteworthy:

- Execution and consolidation of all relevant RAMS-related project activities

- Assigning RAMS-related tasks to the individual members of the project team

- Formation of expert teams (e.g. for FMEAs)

- Coordination of subtasks between main and subcontractor

What are the benefits of a strict RAMS management

according to EN 50126?

With a consistent implementation of the RAMS management process in accordance with the specifications of EN 50126, a minimization of the hazards and faults caused by the systems to be developed and used is ultimately achieved.

In detail, suppliers and operators can achieve the following benefits depending on their areas of responsibility:

- Fulfillment of the specifications for the RAMS process without unnecessary use of resources

- appropriate consideration of safety-related aspects

- efficient management

- Optimization of maintenance strategies and stocking of spare parts

- Secured cost planning and justification of RAMS-related budgets and investments

- Important prerequisite for certification as to ISO/TS 22163 is fulfilled with RAMS-Management

- Comparability and process transparency

What is the position of the RAMS standard EN 50126 on the Common Safety Methods (CSM-RA)?

The risk assessment procedure according to EU Regulations

Technical changes to a system that are implemented with the RAMS management process of the CENELEC standard EN 50126 and the relevant standards for subsystems (e.g.

Project Examples and References

For more than 20 years, we have been providing evidence and analyses for all areas of railway applications on behalf of our customers.

The spectrum of orders ranges from the simple FMEA for suppliers to the long-term assumption of RAMS management for various railway technology trades in the Gotthard Base Tunnel and Ceneri Base Tunnel projects.

Find out about our references!